Basic Info

Model No.: SUF

Applicable industry: Hotels, Food &Amp; Beverage Factory, Construction Works

Out-of-warranty service: Video Technical Support

Where to provide local services (in which countries are there overseas service outlets): Egypt, Philippines, Spain, Chile, Ukraine

Showroom location (in which countries are there sample rooms overseas): Egypt, Philippines, Spain, Algeria, Nigeria

Old and new: New

Machine type: Tile Forming Machine

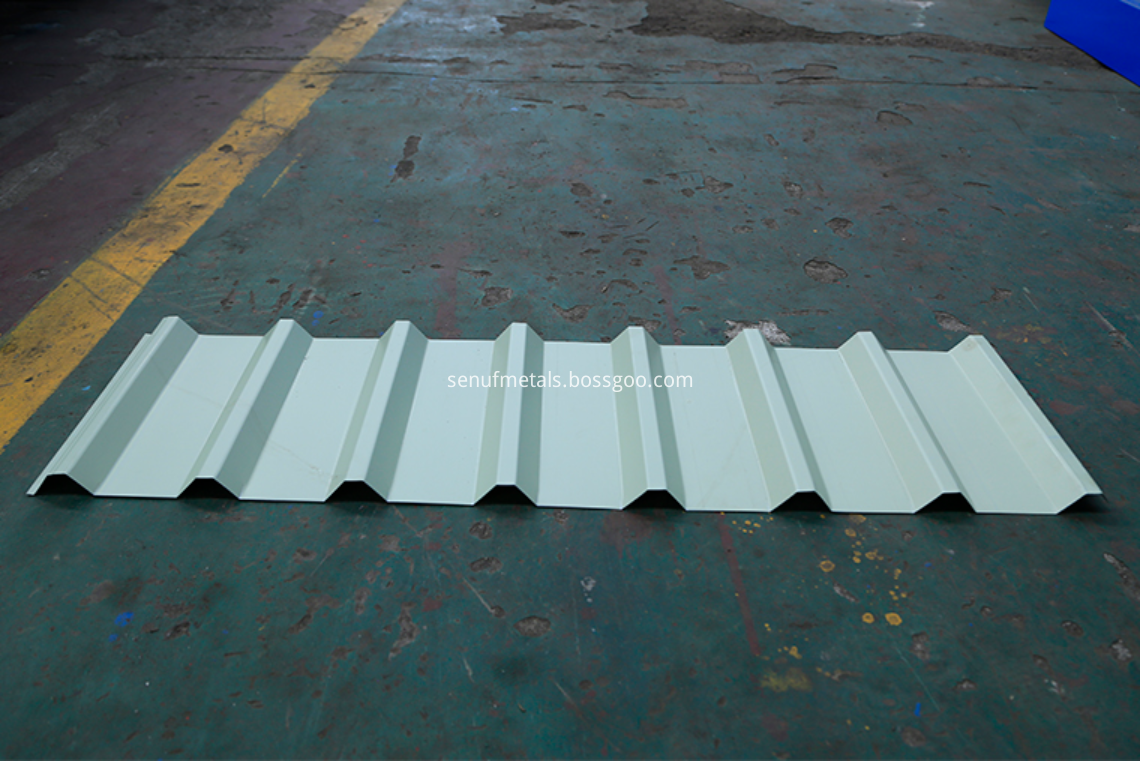

Tile type: Steel

use: Roof

productivity: 30 M/Min

place of origin: China

warranty period: More Than 5 Years

Core selling point: Easy To Operate

Rolling thinckness: 0.3-1mm

Feeding width: 1220mm, 915mm, 900mm, 1200mm, 1000mm, 1250mm

Mechanical test report: Provided

Video factory inspection: Provided

Marketing type: New Product 2019

Core component warranty period: More Than 5 Years

Core components: Pressure Vessel, Other, Bearing, Gear, Pump, Motor, Gearbox, Engine, Plc

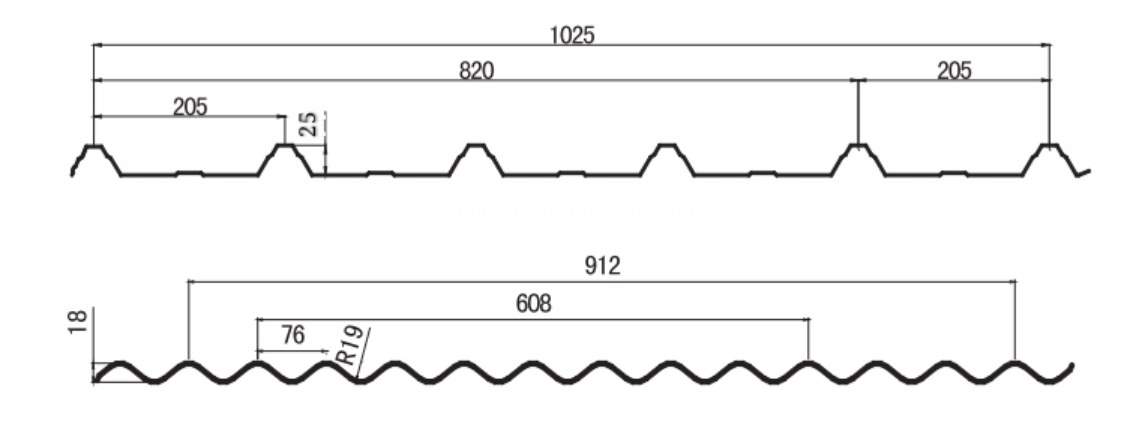

Frame Thickness: 25mm

Thickness: 0.3-0.8mm

Voltage: Customized

Certification: ISO

Usage: Roof

Tile Type: Colored Steel

Condition: New

Customized: Customized

Transmission Method: Hydraulic Pressure

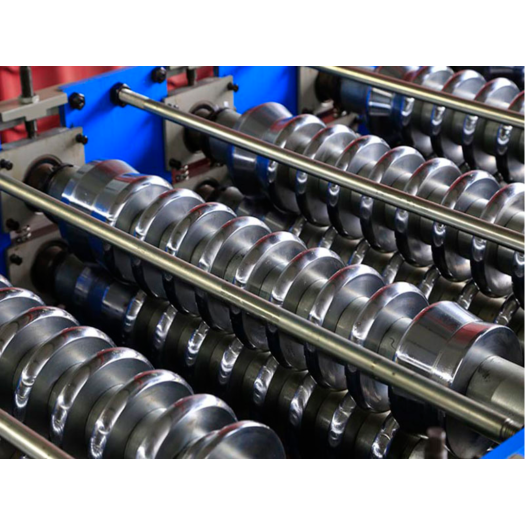

Roll Station: 18 Stations Down Layer And Upper 16

Roller Material: 45# Chrome

Shaft Diameter And Material: ¢70mm, Material Is 445#

Forming Speed: 8-22m/min

.png) Contact Now

Contact Now