Usage:Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate panel.

Main roll forming machine

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Frame: 350 H steel

Drive mode: chain

Material of rollers: 45# steel, surface hard chromium plating.

Length of the main part: 8650*1650*1500mm

Voltage:380V/50HZ3Phase

Roller fixer: middle plate

Material of shafts: 45#steel

Diameter of shafts: φ80mm

Number of rollers: 18 rollers

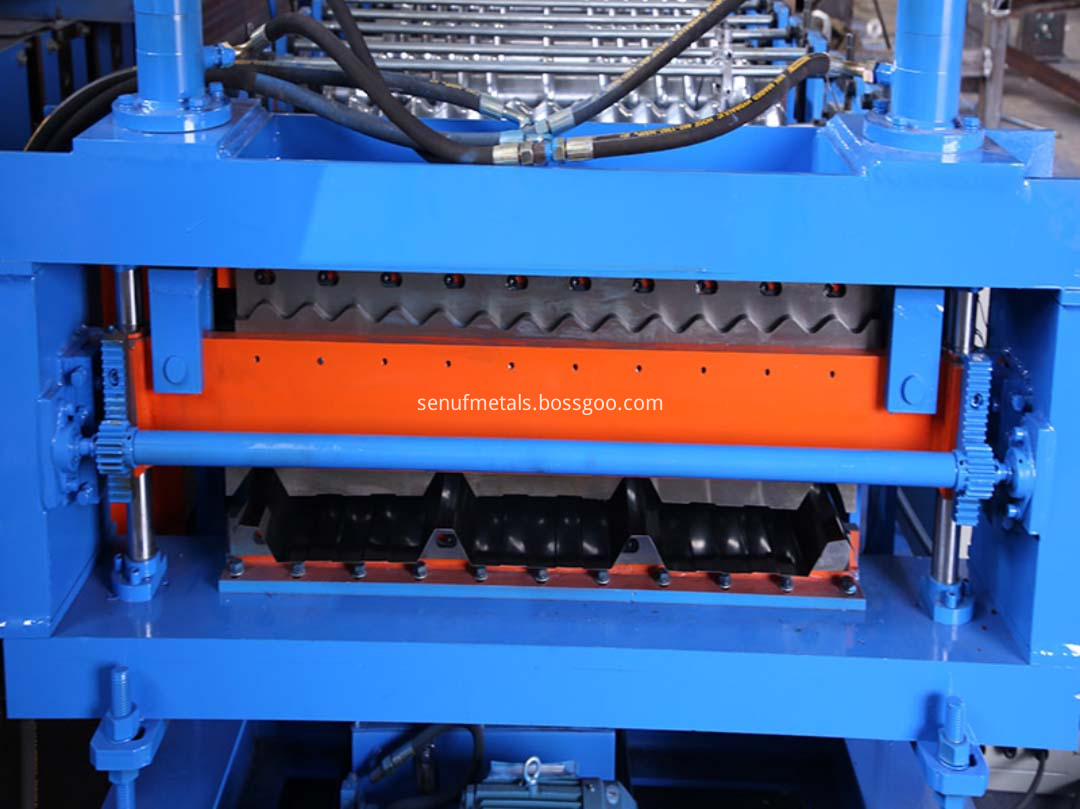

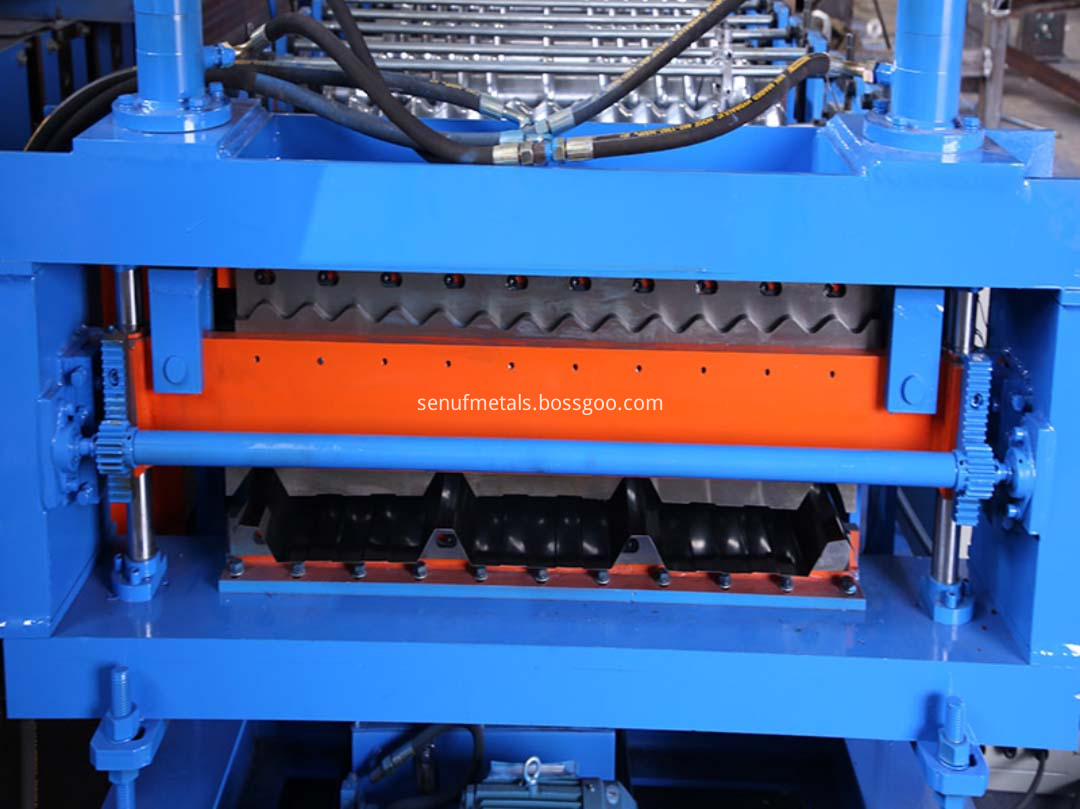

Cutter device

Usage :It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Function: Automatic cutting controlled by PLC.

Material of blades: Cr12 quenched

Power supply : hydraulic power

.png) Contact Now

Contact Now