Product Description

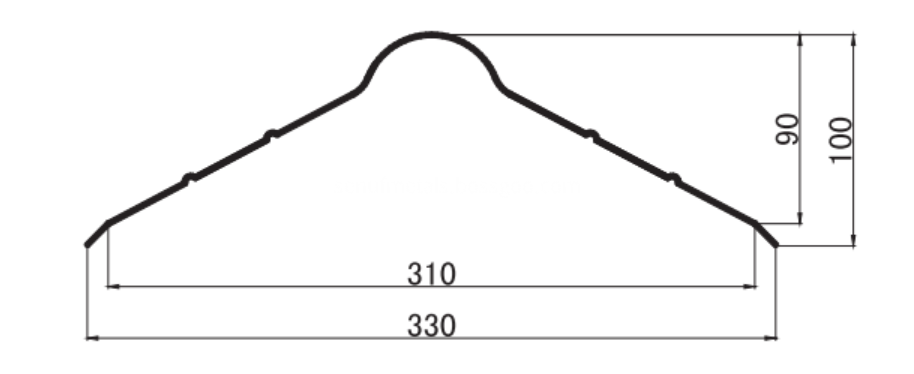

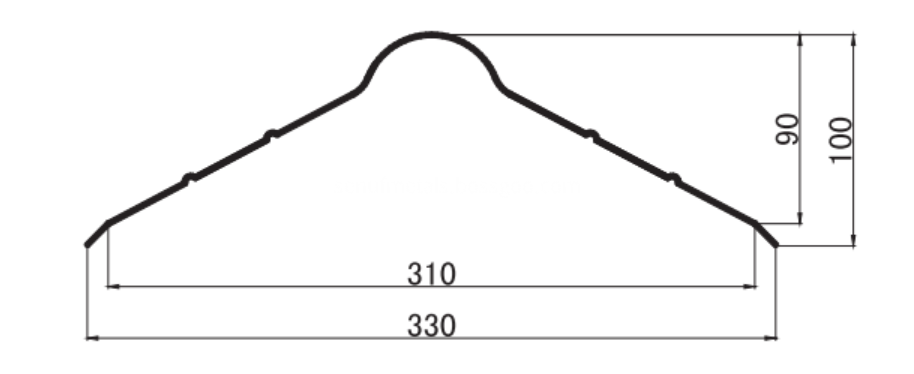

SUF100-330 Ridge Cap Roof Sheet Forming Machine

Main features of SUF100-330 Ridge Cap Roof Sheet Forming Machine

The advantages of Ridge Cap Roof Sheet Forming Machine are as follows:

1. Widely used in many kinds of industrial factory, civilian buildings,

2. Pretty apperance, durable using,

3. Instead using bending machine to make angel tile,

4. Saving human resoureces, lower labor cost

Detailed Images of SUF100-330 Ridge Cap Roof Sheet Forming Machine

Machine Parts

1. SUF100-330 Ridge Cap Roof Sheet Forming Machine manual pre-cutter

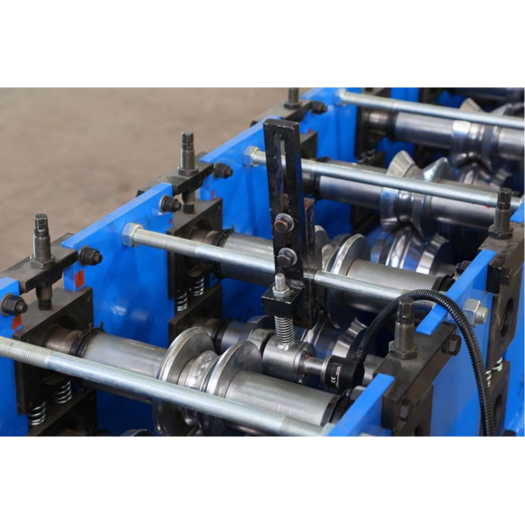

2. SUF100-330 Ridge Cap Roof Sheet Forming Machine rollers

Roller s manufactured by high quality 45# steel, CNC lathes, Heat Treatment, with black treatment of Harf-Chrome Coating for options,

With feeding material guide, body frame made by 400# H type steel by welding,

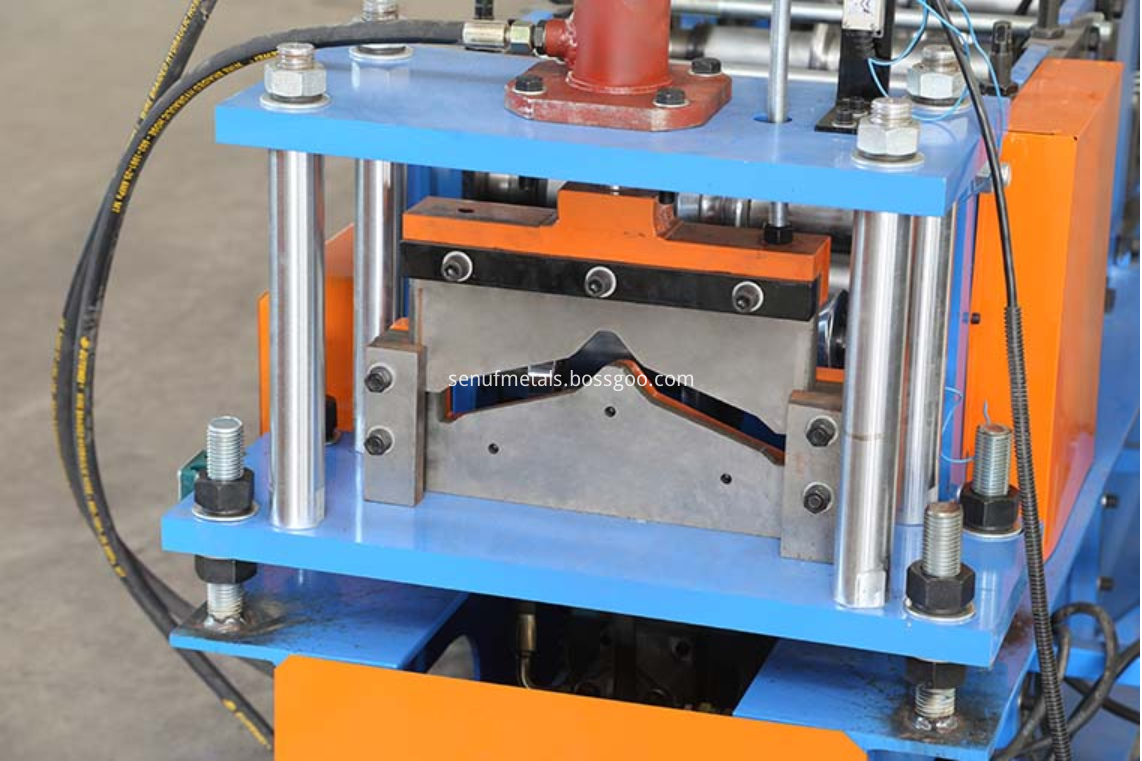

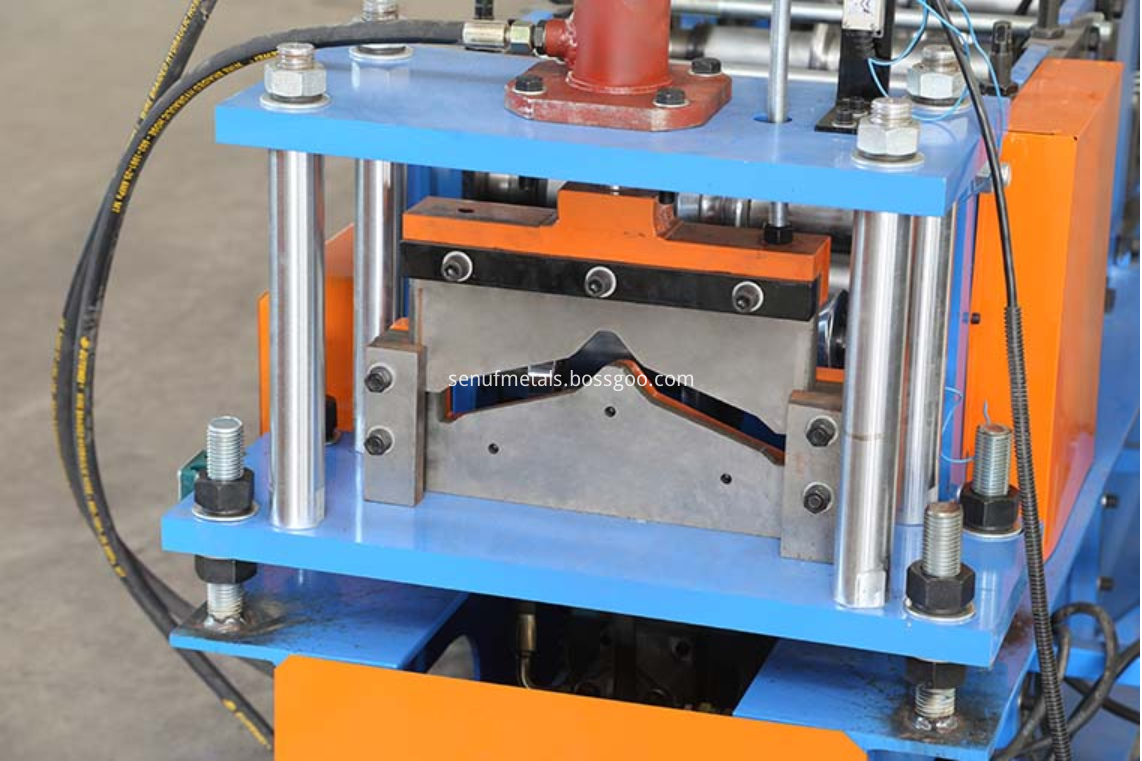

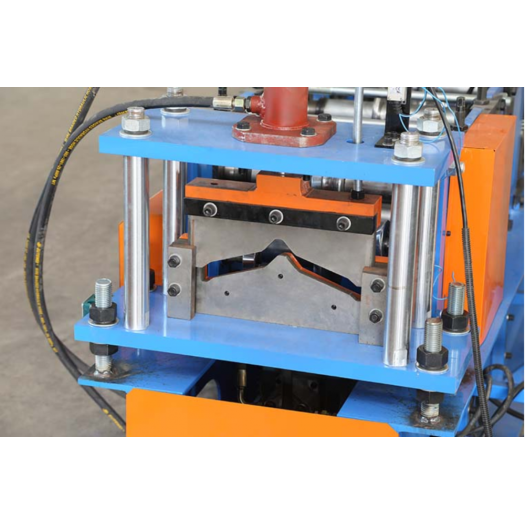

3. SUF100-330 Ridge Cap Roof Sheet Forming Machine post cutter

Made by high quality mold steel Cr12 with heat treatment,

Cutter frame made by high quality 20mm steel plate by welding,

Hydraulic motor: 2.2kw, hydraulic pressure range: 0-16Mpa

4. SUF100-330 Ridge Cap Roof Sheet Forming Machine PLC control cabinet

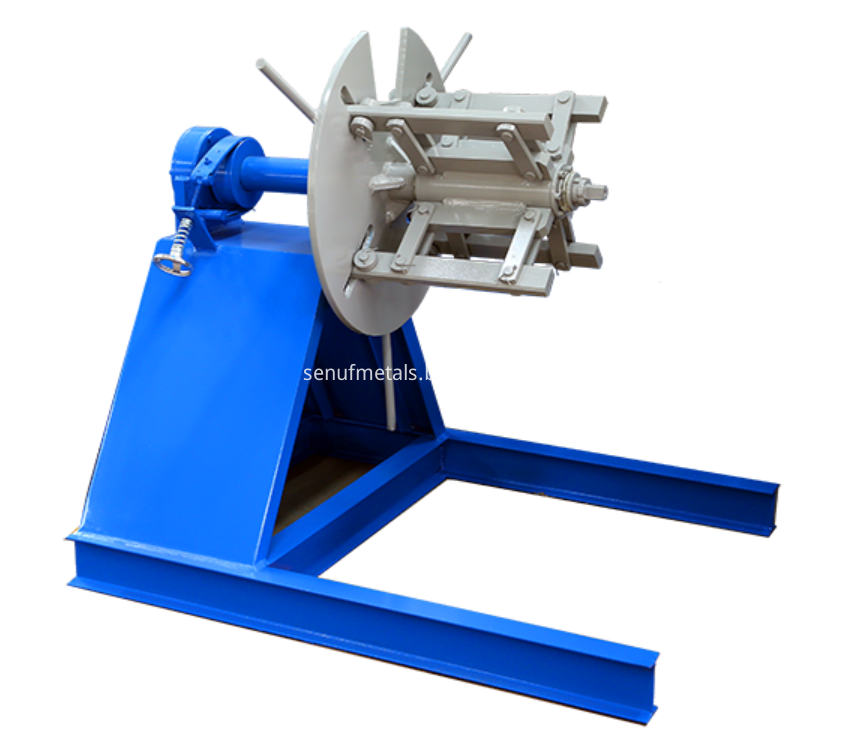

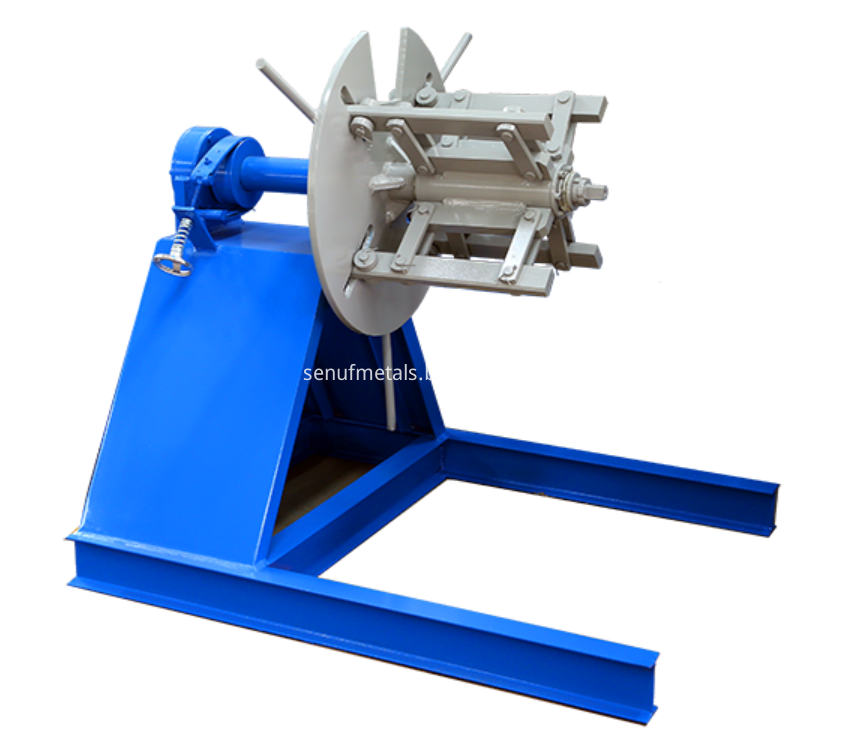

5. SUF100-330 Ridge Cap Roof Sheet Forming Machine decoiler

Manual decoiler: one set

Un-powered, manually control steel coil inner bore shrinkage and stop

Max feeding width: 508mm,

Coil ID range: 470±30mm,

Capacity: Max 3 tons

with 3 tons hydraulic decoiler as optional

6. SUF100-330 Ridge Cap Roof Forming Machine exit rack

Un-powered, one set

Other details of SUF100-330 Ridge Cap Roof Forming Machine

Suitable for material with thickness 0.4-0.6mm,

Shafts manufactures by 45#, main shaft diameter 55/75mm, precision machined,

Motor driving, gear chain tranmission, 10 steps to form,

Main motor 4kw, frequency speed control, forming speed approx 12-15m/min

.png) Contact Now

Contact Now