Product Description

PLC Control Australia Roller Shutter Door Roll Forming Machine

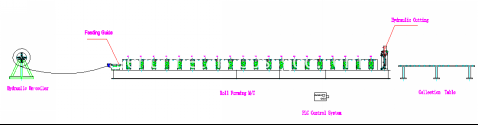

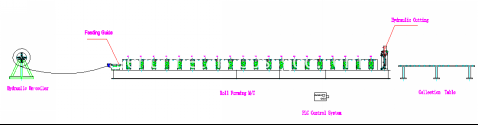

PLC Control Roll Forming Machine with low noise than normal Roller Shutter Door Roll Forming Machine, the complete door roll forming machine line includes decoiler, main machine, PLC control system and exit racks, our machines are equipped with a computer cotrolling system, we simply program the pieces and length we need in the computer and the door machine produces it automatically, the machines are easy to operate and running table.

Main features of Roller Shutter Door Roll Forming Machine

1. Save spaces, more convenient,

2. Easy operation, low maintenane cost,

3. Sable and durable.

Detailed images of Australia Roller Shutter Door Roll Forming Machine

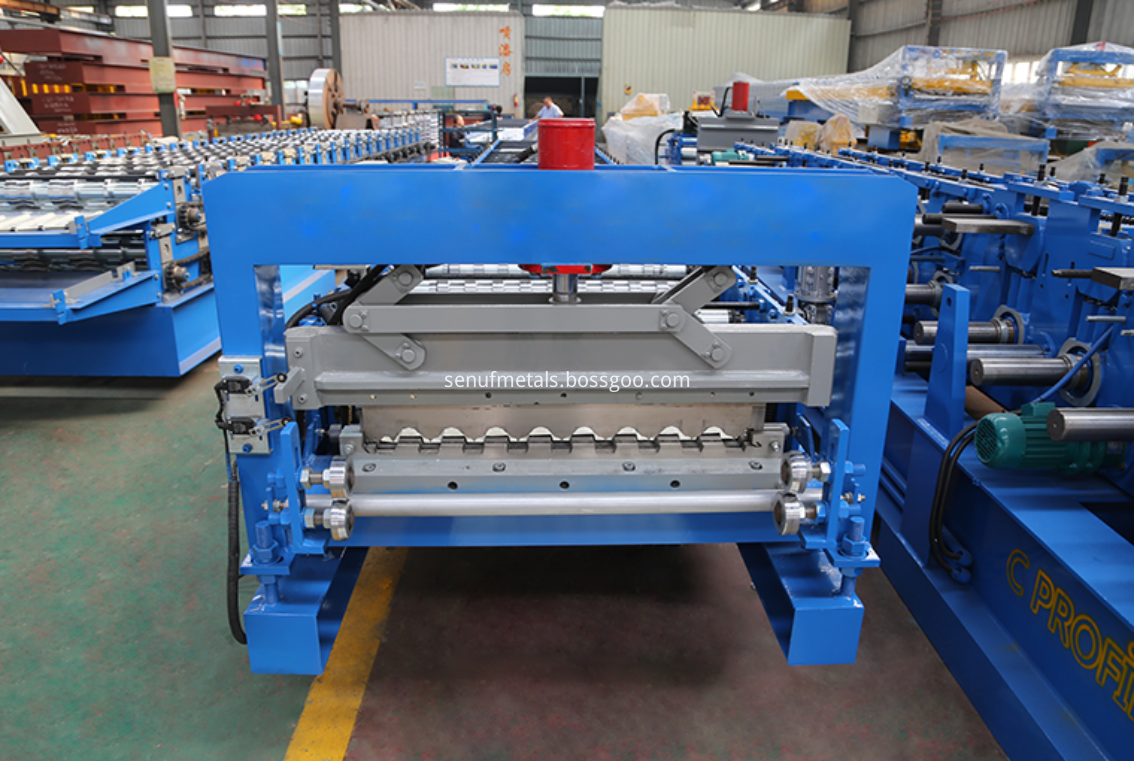

Machine parts

1. PLC Control Australia Roller Shutter Door Roll Forming Machine Pre Cutter

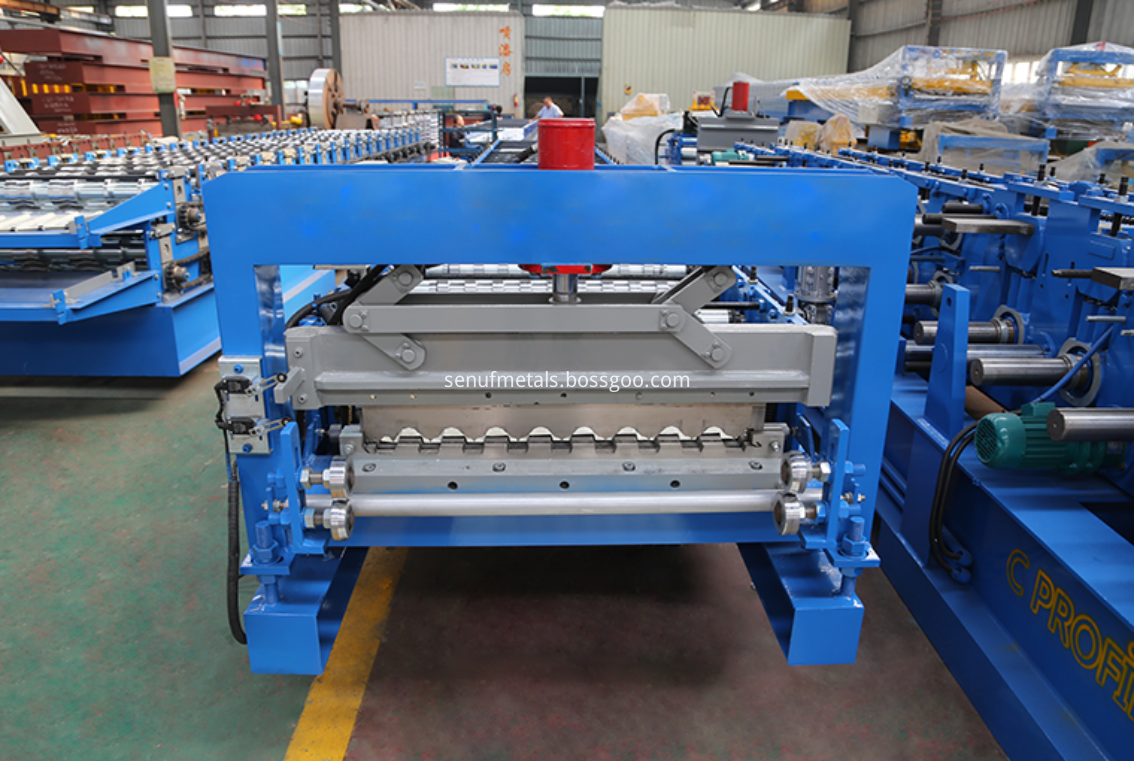

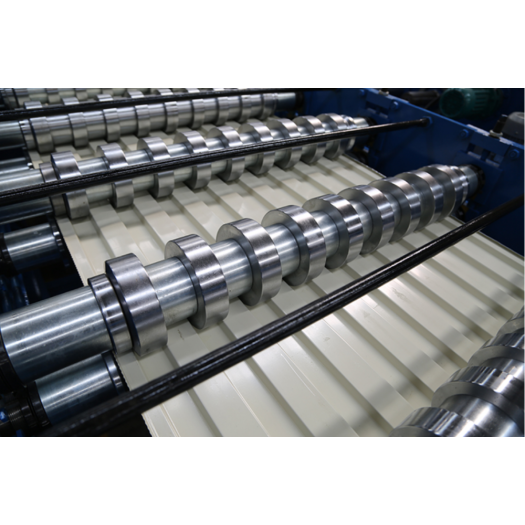

2. Roller Shutter Door Roll Forming Machine Rollers

Rollers manufactured by high quality 45# steel, CNC lathes, Heat Treatment, with black treament or Hard-Chrome Coating for options,

with feeding material guide, body frame made by 400# H type steel by welding

3. Australia Roller Shutter Door Roll Forming Machine Post Cutter

Made by high quality mold steel Cr12 with heat treatment,

Cutter frame made by high quality 20mm steel plate by welding,

Hydraulic motor: 2.2kw, Hydraulic pressure range: 0-16Mpa

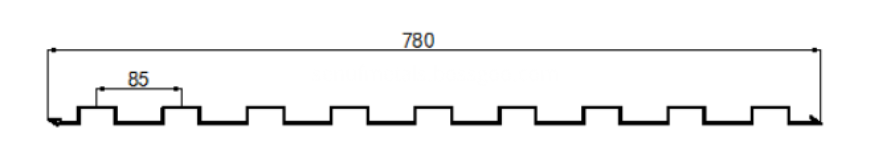

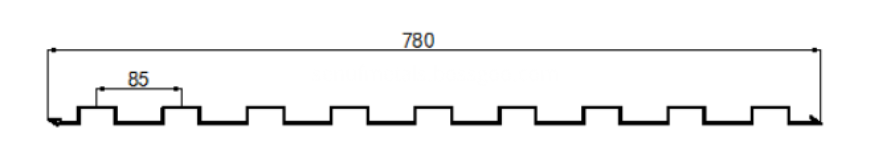

4. PLC Control Australia Roller Shutter Door Roll Forming Machine Product Samples

5. Roller Shutter Door Roll Forming Machine Decoiler

Manual decoiler: one set

Un-powered, manually control steel coil inner bore shrinkage and stop

Max.feeding width: 1250mm, coil ID range 470±30mm,

Capacity: Max 8 ton

With 6 tons hydraulic decoiler for option

6. PLC Control Australia Roller Shutter Door Roll Forming Exit Rack

Un-powered, one set

Other details of PLC Control Australia Roller Shutter Door Roll Forming Machine

Suitable for material with thickness 0.3-0.8mm

Shaft manufactured by 45#, main shaft diameter 75mm, precision machined,

Motor driving, gear chain transmission, 20 steps to form,

Main motor 7.5kw, frequency speed control, forming speed approx 12-15m/min

Contact info: WhtasApp: +8615716889085

.png) Contact Now

Contact Now