Basic Info

Model No.: SUF

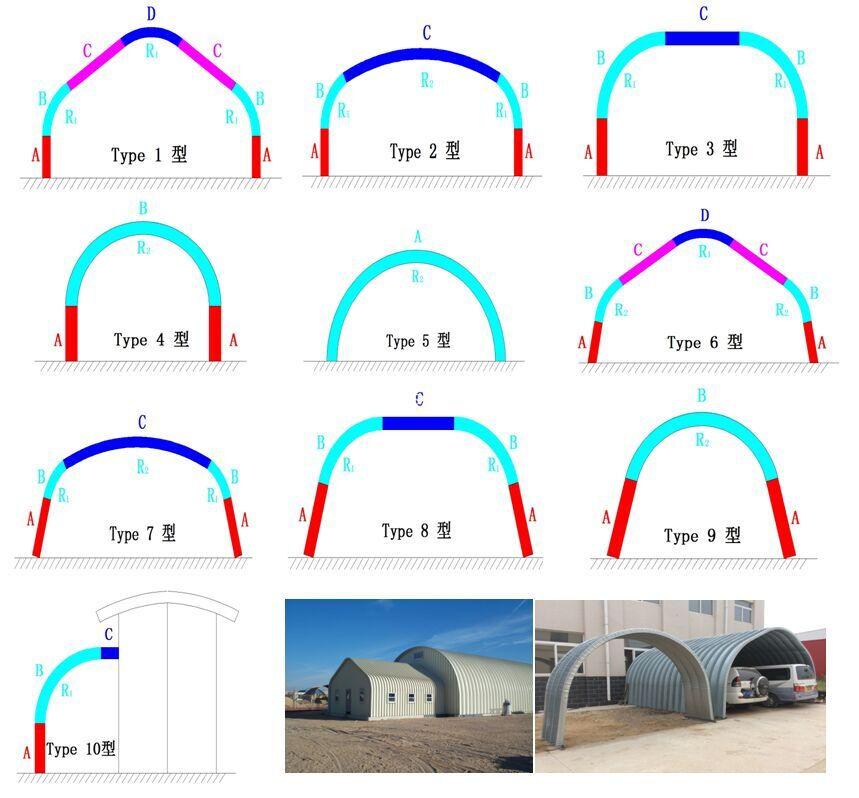

Types of: Steel Frame &Amp; Purlin Machine

Applicable industry: Food &Amp; Beverage Factory, Hotels, Building Material Shops, Farms, Garment Shops, Construction Works

Out-of-warranty service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where to provide local services (in which countries are there overseas service outlets): Italy, United States, United Kingdom, Turkey, Canada, Egypt, Philippines, Ukraine, Kyrgyzstan, Nigeria, Colombia, Morocco

Showroom location (in which countries are there sample rooms overseas): Philippines, Egypt, Spain, Algeria, Nigeria

Video factory inspection: Provided

Mechanical test report: Provided

Marketing type: New Product 2020

Core component warranty period: 5 Years

Core components: Plc, Engine, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump

Old and new: New

place of origin: China

warranty period: More Than 5 Years

Core selling point: Easy To Operate

Motor Power: 7.5kw

Control System: PLC

Shaft Material: 45#steel

Voltage: Customized

Certification: ISO

Condition: New

Customized: Customized

Automatic Grade: Automatic

Structure: Horizontal

Transmission Method: Machinery

Material Of Cutter: Cr12 Steel

Thickness: 0.6-1.5mm

Cutting Power: 3.0kw

Bending Power: 4.0kw+1.5kw+1.5KW

Material Of Rollers: 45#steel, Quenched HRC 52-58

Forming Rollers: 13 Steps

.png) Contact Now

Contact Now