Product Description

For Serbia Glazed Steel Tile Making Machine

Glazed Steel Tile Making Machiner for Colored Glazed Steel Roofing Sheet is used to make the color glazed tiles in batch by the Steel Roof Tile Making Machine. the finished product of Glazed Steel Tile Making Machine For Colored Glazed Steel Roofing Sheet is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance and grace taste. This machine working speed is around 4-5 meter per minutes.

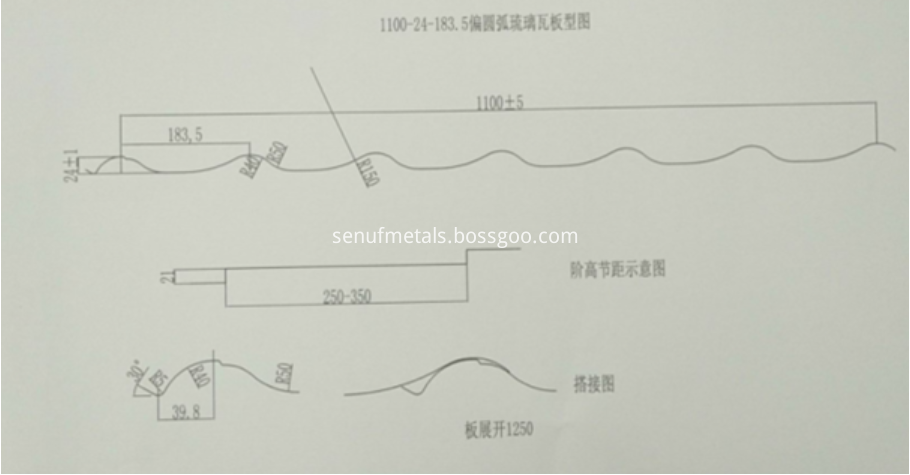

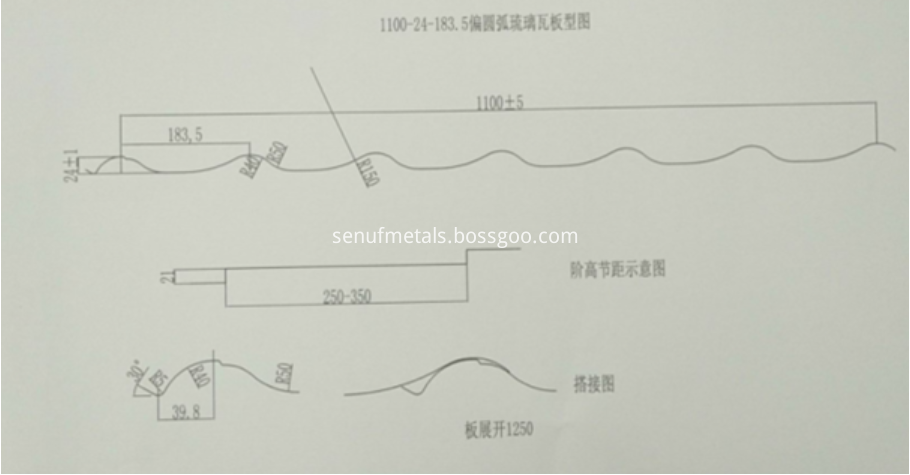

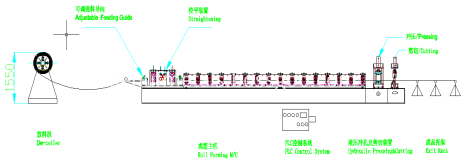

Taking the drawing profile we made for Serbia for example to show you how the machine is made:

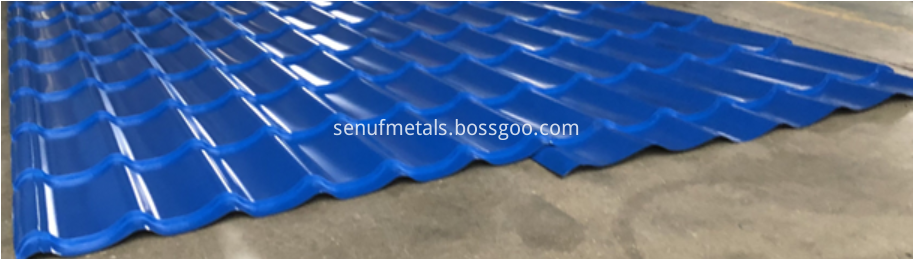

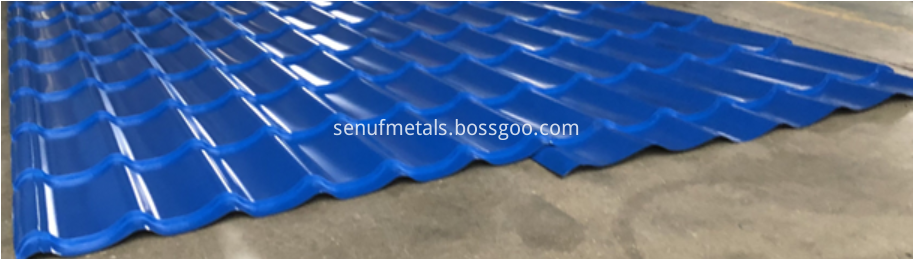

Based on this drawing, we made the Glazed Steel Tile Making Machinery like this:

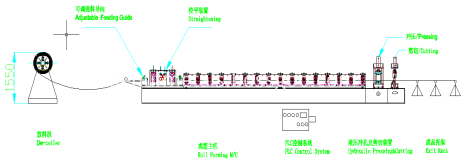

Glazed Steel Tile Making Machine Working Process:

Decoiling---Roll forming--- Cut to length---Final product

Glazed Steel Tile Making Machine components:

Roll Forming Machine:

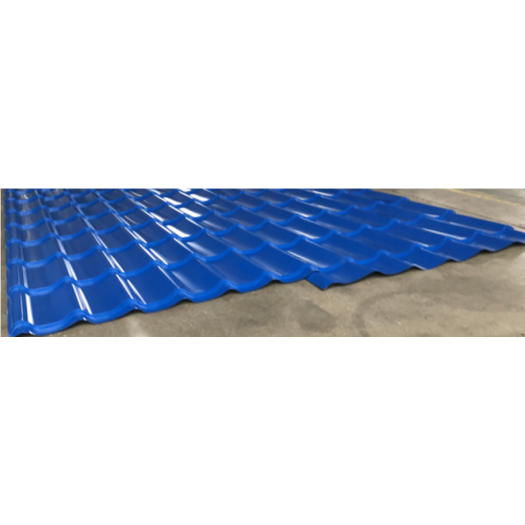

Profile of colored steel panel produced by this type of roll forming machine:

Profile drawing of Glazed Tile Making Machine

Effective width: 1100mm

Feeding width: 1250 mm

Thickness of formed steel: 0.3-0.6mm (usually the thickness of the sheet is less than 1 mm)

Material of coil or plate: GI, PPGI

Picture of roll forming machine (just for reference)

Parameters of roll forming machine

(1) Material of frame: (high grade) 400 mm`H` shape steel welding

(2) Thickness of whole plate not welding middle plate: 20mm

(3) Step of roller: 13 steps

(4) Diameter of shaft (solid shaft):74 mm

(5) Material of shaft (solid shaft): (high grade) 45# Steel,quenching and tempering treatment

(6) Material of roller: 45# Steel

(7) Treatment of roller: hard chromize coated 0.05-0.07mm

(8) Drive type of roll forming machine: drive by chain

(9) Chain: 25.4mm (high grade)

(10) Bearing: 6210 (high grade)

(11) Reducer: 5# cycloid reducer (high grade)

(12) Power of main motor: 5.5KW

(13) Voltage: 380V/50Hz/3phase

(14) Motor power of hydraulic station: 5.5kw

(15) Line speed: about 3-5 m/min

(16) Oil pump of hydraulic station: gear oil pump (high grade)

(17) Hydraulic cutting: cutting controlled by PLC

(18) Accuracy of cutting: +/- 2mm

(19) Razor blades material: Cr12, quenching 58-62 °.

(20) Appearance size of main forming machine: 7m (length)*1.6m (width) *1.4m (height)

(21) Electrically controlled system: entire machine controlled by PLC

(22) PLC : DELTA(TAIWAN)

(23) Frequency converter : DELTA(TAIWAN)

(24) Frequency converter power: 5.5KW

(25) Encoder: ROUNDSS (high grade)

(26) Controlling desktop: text screen (high grade)

(27) Electrical parts: DELIXI or CHINT

Except this drawing profile, our Glazed Steel Tile Making Machinery for Colored Glazed Steel Roofing Sheet also could be used to make the following types:

.png) Contact Now

Contact Now