Product Description

Automatic roofing sheet curving machine

Material:

Material thickness: 0.3-0.8mm

Applicable material: GI, PPGI with the yield strength 235-345 Mpa

The machine features:

The panel forming machine is mainly used to make the profile panel become curved with the required radius through cramps on the surface, It can realized auto control and the curving radius length and cramp-distance are adjustable through setting on the screen and PLC cabinet

Machine components:

Hydraulic motor: 4kw, feeding motor with servo type motor,

Curving radius: min 500mm,

Horizontal and vertical two optionals.

PLC control system:

Control the quantity and cutting length automatically,

Input the production Data (Production Batch, pcs, length, etc) on the touch screen,

It can finish the production automatically,

Combined with: PLC, Inverter, Touch Screen, Encoder, etc.

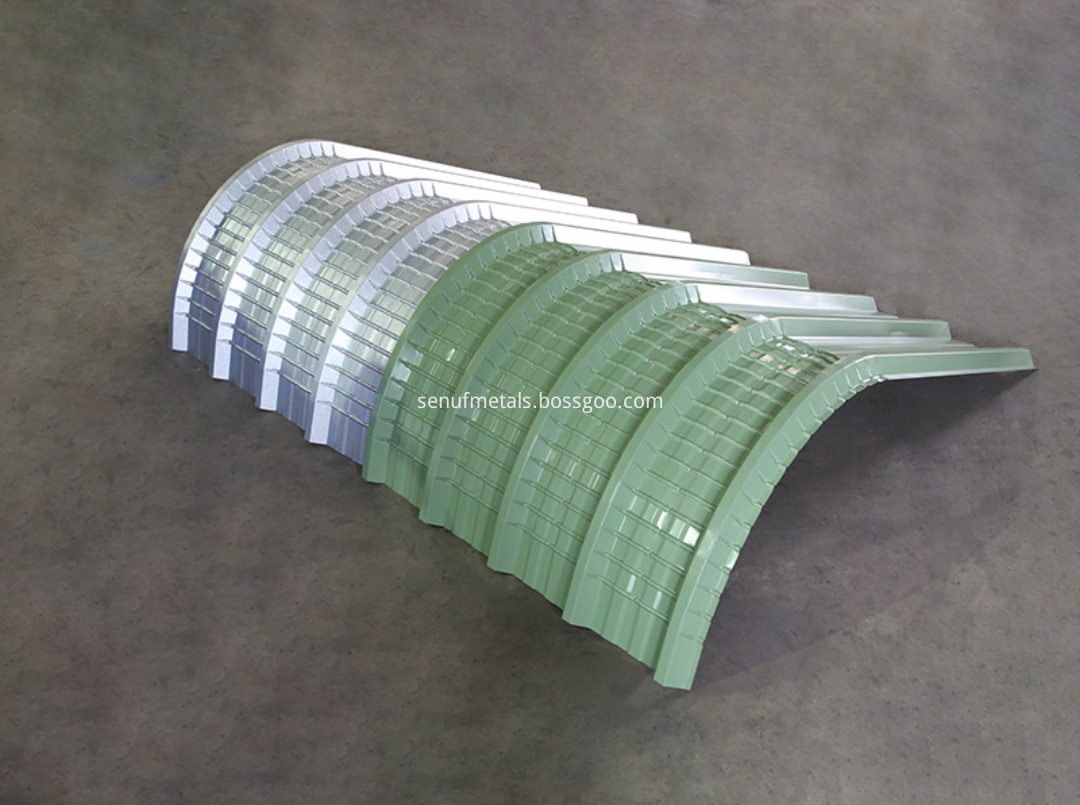

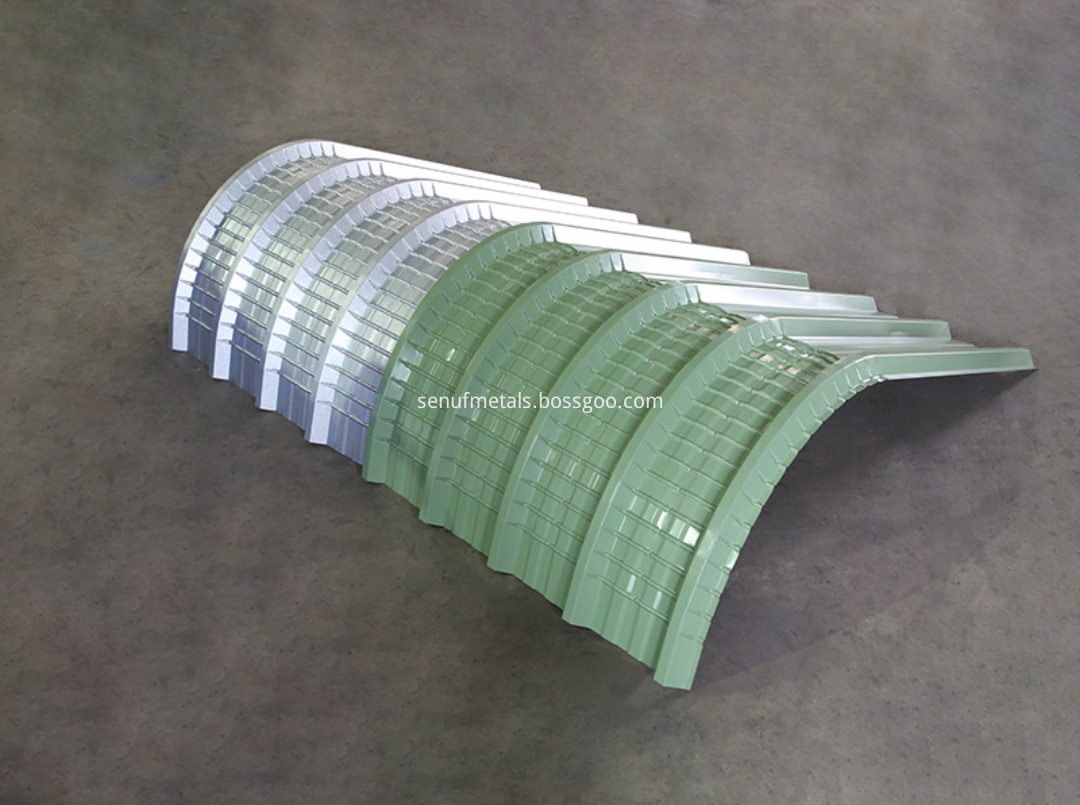

Product show:

Contact info: WhtasApp: +8615716889085

.png) Contact Now

Contact Now