Product Description

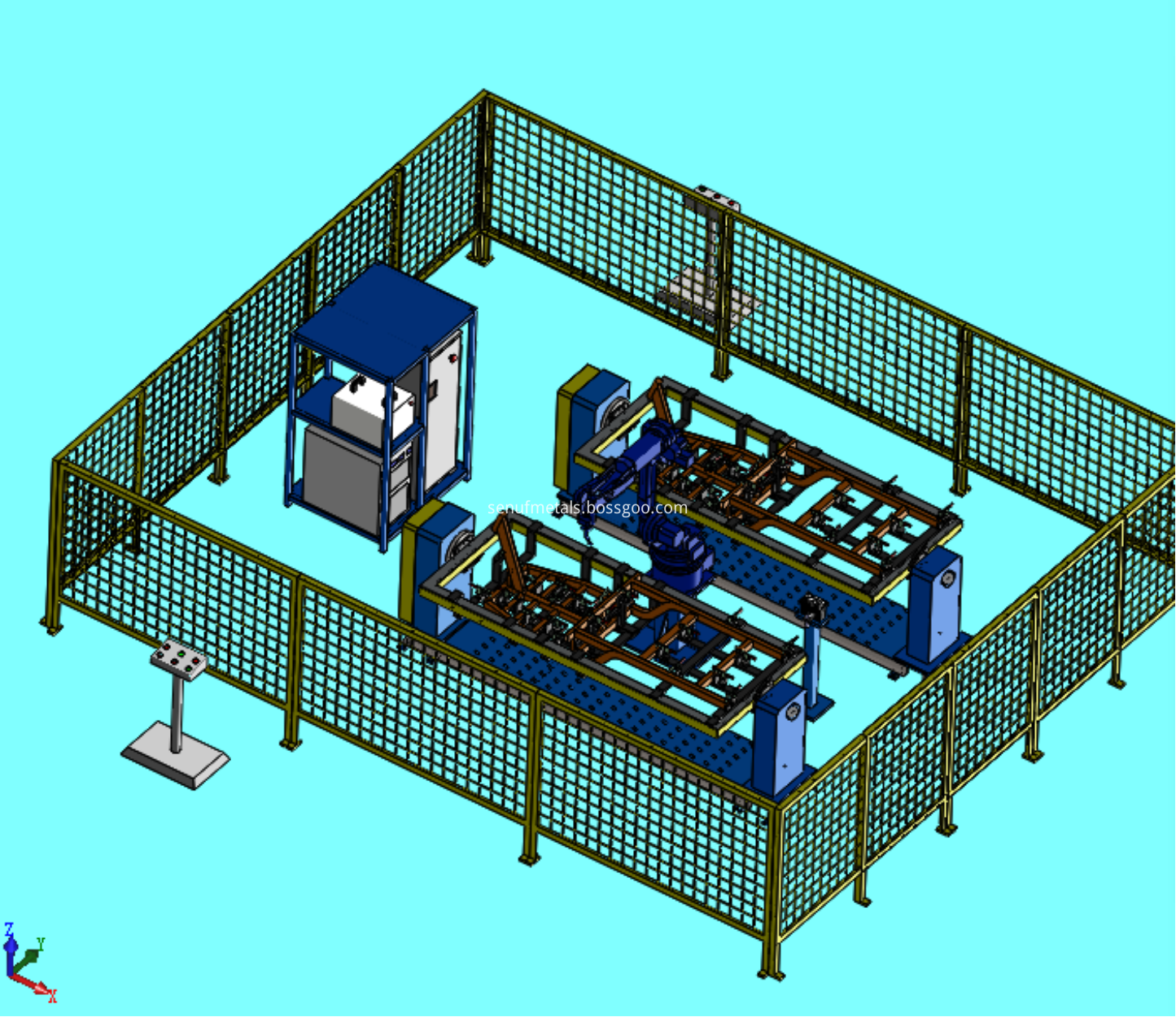

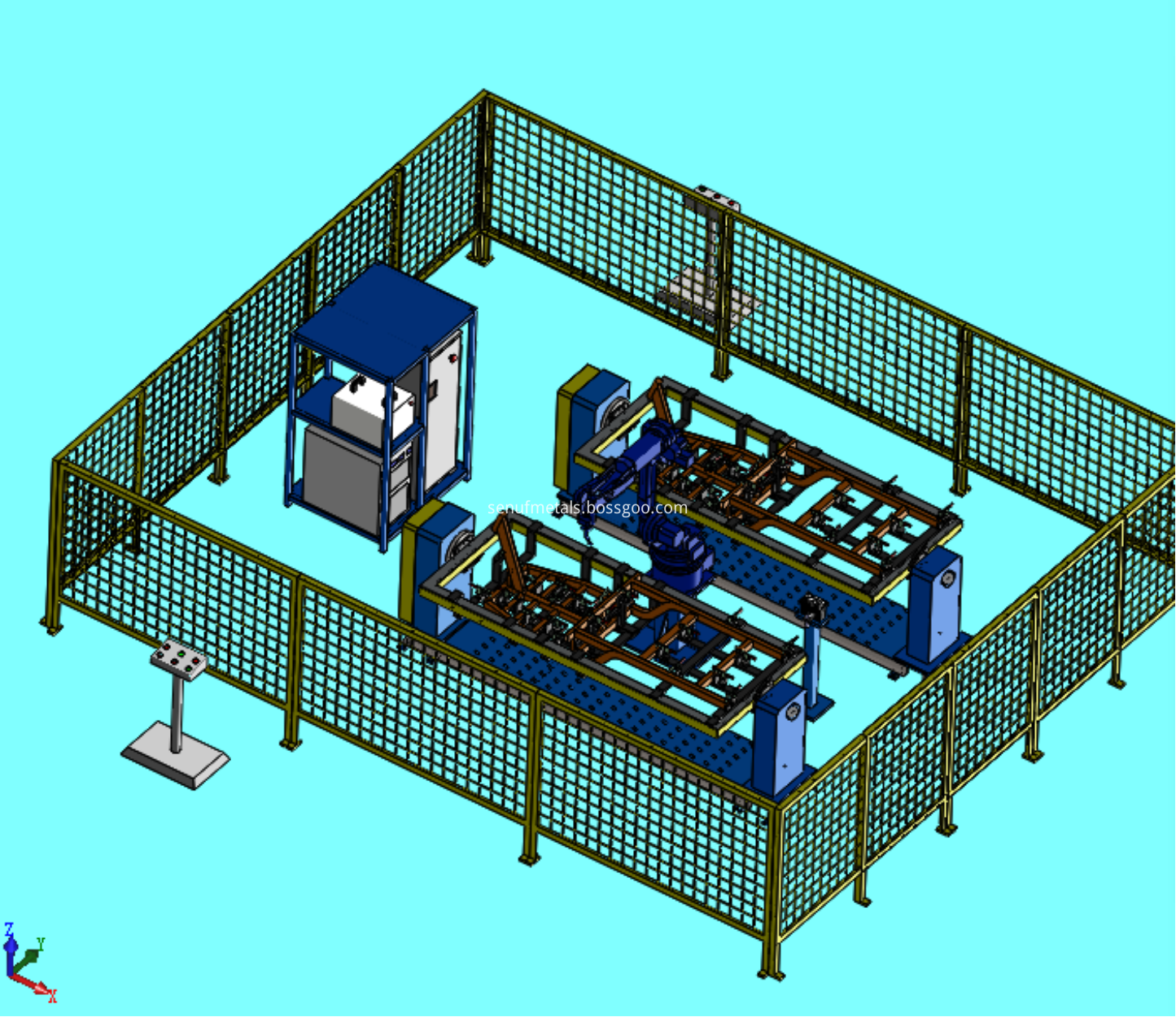

1.1.Schematic sketch of workstation

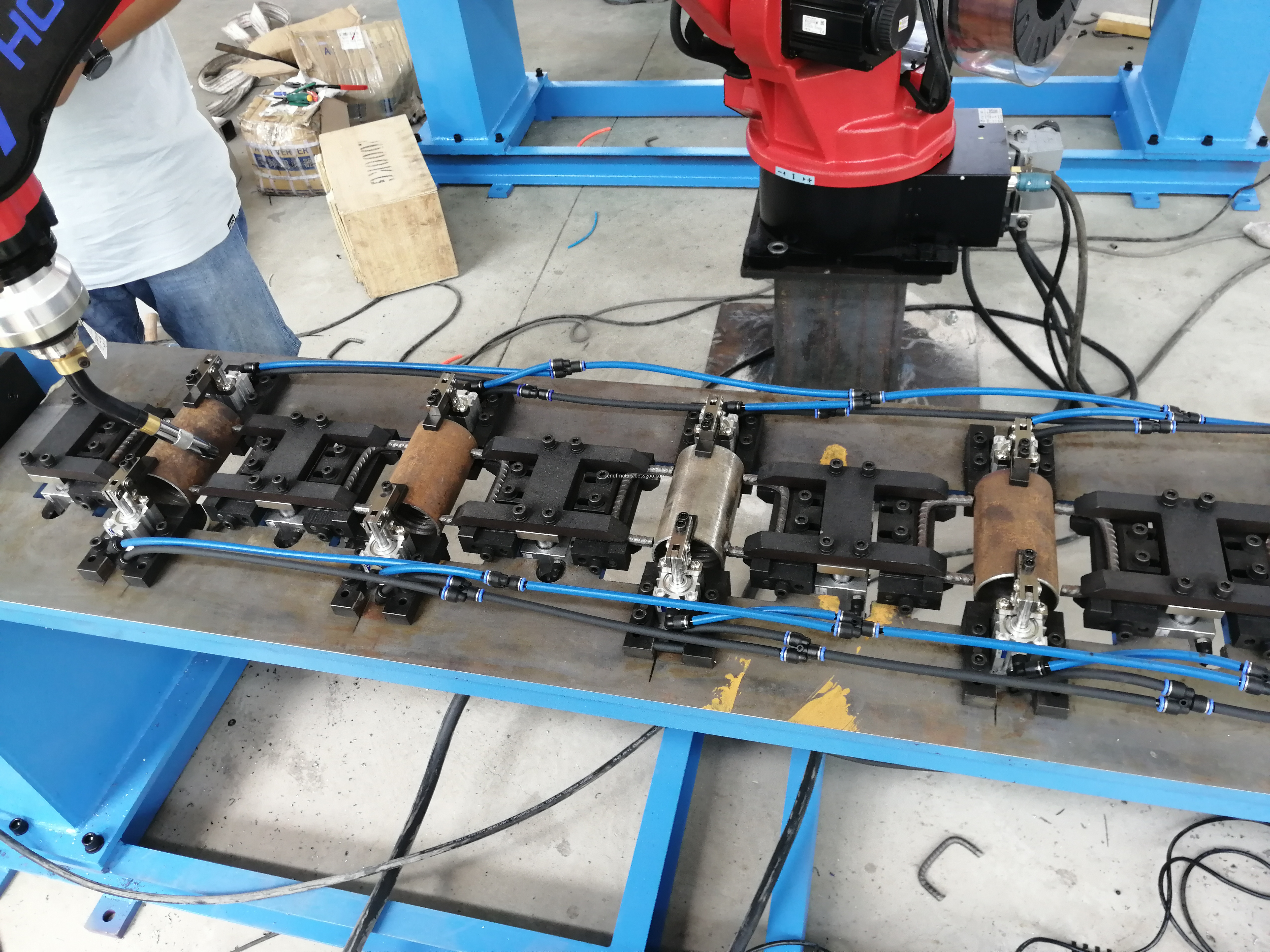

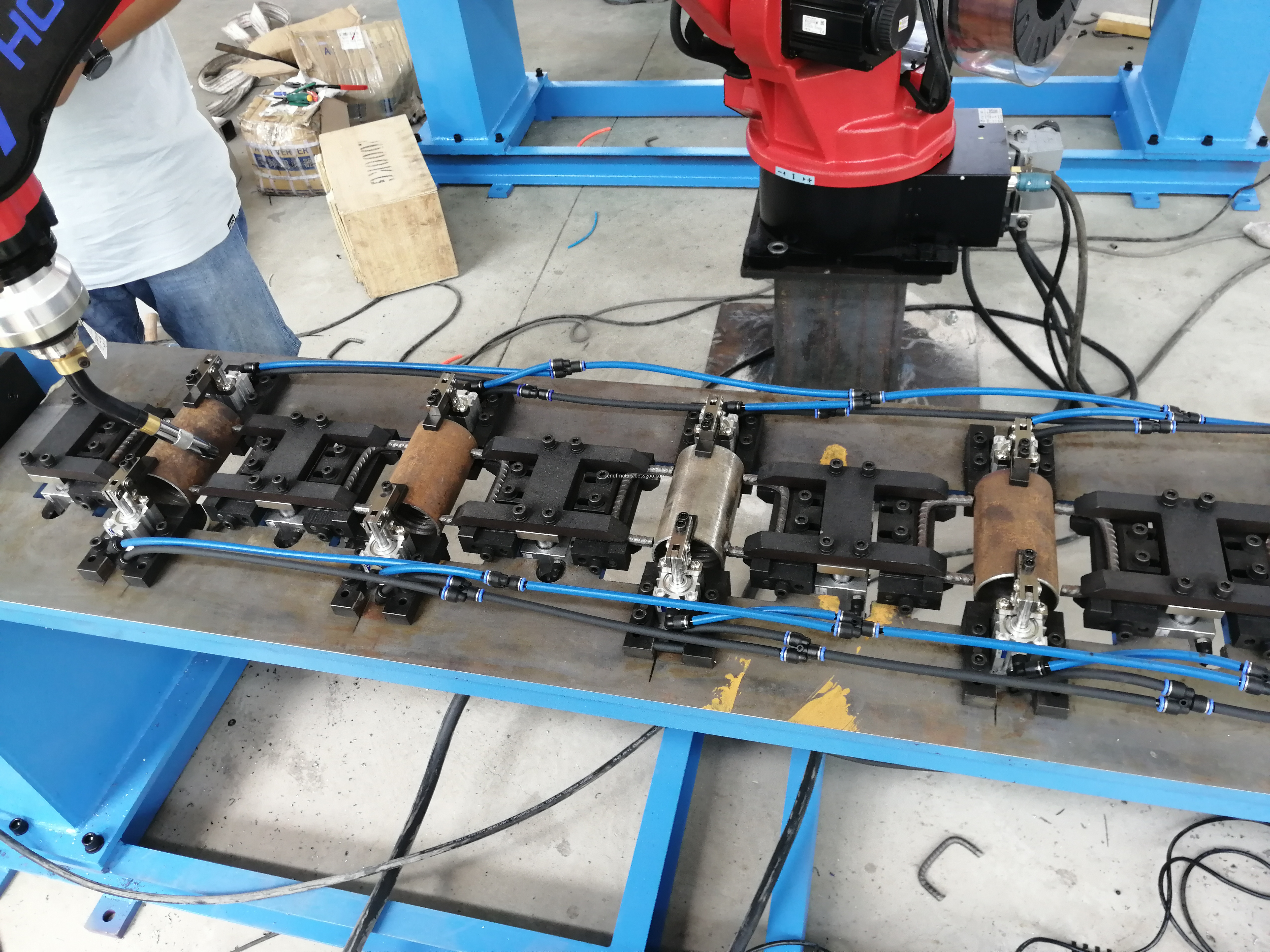

The workstation adopts multi-station design, and its layout is composed of an Anchuan welding robot MA14400, RD350 digitized low spatter gas welding machine, two uniaxial welding positioners, one robot base and two welding tooling bases.

1.2. Introduction of Functions and Characteristics

The welding robot has the advantages of high precision, high speed and high working efficiency. The control system is sensitive and reliable, with fewer faults and convenient operation and maintenance. Starting, stopping, suspending and emergency stopping of the system can be carried out through the teaching device. In addition, the running state of the system and the alarm of the system can be displayed on the instructor.

The welding robot has the advantages of high precision, high speed and high working efficiency.Welding robot operation and high precision, speed, and greatly improve the work efficiency.Welding robot operation and high precision, speed, greatly improve work efficiency.Welding robot operation of high precision and fast speed, greatly improving the work efficiency.Welding robot operation and high precision, speed, greatly improve the working

Welding power source adopts RD350 function digital gas shielded welding machine. Low spatter, easy arcing, soft and stable arc, high metal deposition rate, good weld formation.

The device defaults to blue in appearance. To use other appearance colors, the user should confirm in writing before making them. We will produce them according to the color specified by the user.

The workstation has signal interlocking and interlocking among various actions to prevent the occurrence of misoperation, so as to improve the overall performance of the whole workstation.

Technical parameters of main equipment

3.1. Welding Robot

1) Technical parameters

Note: The company reserves the right of final interpretation of product specifications.

2) Scope of action

2) Performance characteristics

Excellent performance, high processing power of main CPU, high speed of operation

More precise control of the trajectory of the robot to make the robot run fast and smoothly

With multiple interfaces, external devices and data connections are more convenient

Wide adaptability to temperature and humidity and easy maintenance

3.3. Instructors

1) Technical parameters

2) Performance characteristics

3.4, RD-350 Functional Digital Inverter Welding Power Supply

1) Performance characteristics

The optimum droplet transfer form for pulse welding is one droplet transfer by pulse. By adjusting the pulse frequency, the number of droplets per unit time can be changed, that is, the wire melting speed.

The excessive droplet form improves the melting coefficient of the welding wire, that is to say, the melting efficiency of the welding wire is improved. Welding speed can be increased by 30%.

The weld has good shape, large melting width, weakened finger-like penetration characteristics and small residual height. Due to the excessive droplet droplets in one pulse, the droplet diameter is roughly equal to the wire diameter, and the droplet arc heat is low. All welds have fine grains and high strength.

The arc has good directivity and is suitable for all-position welding.

Compared with ordinary welding machine, the noise is obviously reduced, the interference is reduced, the operation is more comfortable and the energy is more concentrated.

Pulse gas shielded welding machine is a kind of welding machine which uses the excessive droplets of pulse current time to realize spatter-free welding, eliminates the labor of cleaning the spatter on the surface of the weld, and makes the weld formation more beautiful. At the same time, due to the low droplet temperature and less welding smoke, it greatly improves the construction environment.

3.5 position changing machine

The turning position machine is used for turning the workpiece. It can turn the work to the ideal welding position for welding, so as to improve the quality of welding seam and improve the welding efficiency.

Welding positioner is used for workpiece positioning in welding process. Baselines are inscribed on the worktable, various positioning workpieces and clamping mechanisms are installed, and grooves are installed to make the worktable face have higher strength and impact resistance.

3.6 Single Axis Positioning Machine

The main function of the welding positioner is to rotate the workpiece during the welding process so as to obtain the best welding position and meet the requirements of welding quality and appearance.

The base of the positioner is welded with high-quality profiles and steel plates. After annealing treatment, the quality is reliable.

Rotation is driven by servo motor and reducer is driven by high precision reducer. It has reliable precision and adjustable speed. It can be linked with robot.

Contact info: WhtasApp: +8615716889085

.png) Contact Now

Contact Now